Today's tires represent the revolution in chemical synthesis technology that has occurred since the original introduction of bicycle and auto tires a century ago. While the tires of old generally consisted of natural rubber that wore out quickly and was simply bolted onto car axles with steel, today's include a variety of reinforcing fabrics, age resistors, dyes, and other chemical based products that are attached to vehicles using copper, tin, zinc, and chromium coating (au.gov). Nearly all of the chemicals used to resist age and make tires stronger are made from petrochemicals; petrochemicals are petroleum based; oil is petroleum based; thus, all the environmental challenges posed by petroleum extraction apply to tire production.

Emissions

The fact that the EPA, a reasonably defunct agency under the Bush Administration (despite the pleasant logo), has taken measures to reduce emissions from rubber tire manufacturing underscores the damage resulting from the manufacturing process. The EPA lists the following as areas of interest concerning "air toxics" - 1) operations using solvents and cements at tire production facilities, 2) tire cord production, and 3) puncture sealant applications.

The EPA then lists a series of chemicals known to cause cancer in humans; (see EPA air toxics) other possible health consequences include chronic nervous and reproductive system disorders, as well as similar, but more acute problems (epa.gov).

All of these stem from both the creation and destruction of synthetic tires. Since both processes require extreme heat and chemical shifts within the tire's composition, the result is, quite simply, tire petrochemicals in the air.

The US government also admits that the chemical creosote can be heated and then made airborne through the process of burning scrap tires in cement kilns, a very popular method of waste removal. Creosote can cause a variety of negative effects on human health, notably cancer (cdc.gov).

Tire Burning

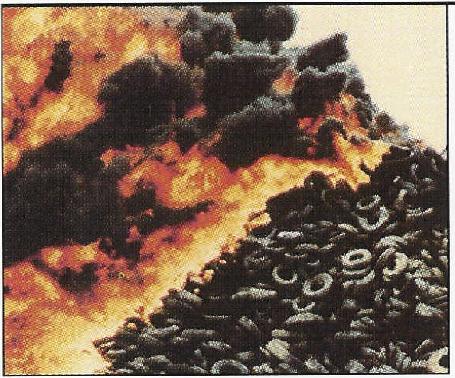

The act of burning tires as a method of waste removal is popular in both the industrial and public spheres. Industrially, as mentioned briefly above, the act generally occurs in large cement kilns; the EPA has identified countless chemicals (including dioxin, arsenic, lead, cadmium, chromium, chloromethane, etc) deemed harmful to human health within emissions produced by the burning. Of these, the EPA has labeled dioxins as the most harmful. Produced by industrial processes involving chlorine, the EPA website lists dioxin exposure as a major cause of cancer and leukemia in humans.

The graphic above, from the EPA, highlights industrial waste removal as the primary source of dioxin introduction into the atmosphere; then, dioxins spread into crops and other sources of human food, eventually ending up being consumed by people.

The act of burning scrap tires has generated widespread condemnation of industrial plants across the US. From Montana (notoxicburning.org) to Vermont (lesspollution.org), with countless states in between, citizens have organized to demand emission caps and policy changes to address the problem. Citing EPA studies on dioxins and creosotes (among others) dating back to 1984, these organizations have achieved limited success. Often, intense public scrutiny and protest lead factories or firms to relocate or adjust burning policies; however, without federal laws governing the practice of burning tires, it is certain to continue.

EPA Action?

Despite the lack of decisive action taken by the EPA to combat emissions from tire burning, they have addressed the urgency of the situation by offering promulgated rules, or rules that will soon be enacted if legislation passes. To address the previously mentioned "areas of concern", the EPA has declared the following promulgated rules:

- Tire Production Operations - Forced to reduce toxic air emissions by roughly 100%

- Tire Cord Production Operations - Forced to reduce toxic air emissions by 72%

- Puncture Sealant Operations - Forced to reduce toxic air emissions by 86% (existing facilities) and 95% (new facilities)

These measures, if ever enacted, are decent approaches to the problem. However, they reveal a fundamental problem concerning the way the EPA addresses environmental problems: each measure seems to be a compromise between corporate concerns and environmental concerns. When emissions from tire burning should be completely eliminated given their harmful nature towards humans, they are only reduced once over. If not eliminated completely, these measures should be increased. Interestingly, consumers will be the most likely to pay for these measures, not the corporations being "hassled"; even still, the EPA estimates that the total cost to consumers will be less than one cent per tire. Surely, it would be a safe bet to assume the public would pass a referendum that asked them to choose between more expensive tires (5 cent increase) and an elimination of toxic carcinogens from tire burning.

The optimist would suggest that the EPA is only being economically cautious. One can only hope that the EPA truly means to eliminate these emissions entirely in the future, which would suggest that this is only the beginning in a series of measures.